We are leading an initiative to accelerate the production of personal protection masks to donate to local and global medical staff against COVID-19.

CORONAVIRUS COVID-19 PANDEMIC

Since its outbreak, the Coronavirus pandemic that is shaking the entire world has registered more than 400.000 cases to date, hitting hardest in China, Italy, the USA, and Spain – in particular Madrid its surrounding provinces such as Castilla y León, where Nagami is based.

Hospitals across the global are running at beyond maximum capacity and their need for safe medical equipment has grown exponentially in the past few days. To speed up the supply of essential items such as masks and life support machines, manufacturers are using 3D printers and other digital manufacturing tools, and are forming a global network where on-demand production can be actioned locally.

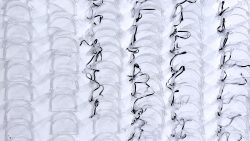

We have the furniture production on hold to focus exclusively on the production of robotic 3D printed COVID-19 Masks based on the Prusa model, which is open source and can be reproduced by desktop 3D printers. By designing a specific robotic version of the model and thanks to its extrusion technology, Nagami is printing around 500 COVID-19 Masks per day — or one mask every five minutes — around seven times faster than a desktop 3D printer, and the company is working around the clock in collaboration with the entire local community.

“

This is by far the most important project we’ve ever worked on, but also one we wish we’d never had to start. Our generation has knowledge and digital tools that have become truly meaningful. There is no product to sell, no market to compete in. This is a challenge for all of us, and we’d like to encourage everyone with tools of any kind to reach out and contribute to helping bring safety back into our world

Nagami Team

”

Nagami is currently focusing its efforts on covering Ávila’s needs, in the city where its factory is located, and is planning to expand this week to other regions such as Madrid and La Rioja. Inquiries are arriving from various other countries, such as the USA, Italy, France, UAE, India, UK, Denmark, and many more.

The masks are produced through robotic extrusion in a layer-by-layer FDM (fused deposition modelling). The material used is a PETG (Polyethylene Terephthalate Glycol) which is durable, tough, 100% recyclable, and has robust chemical resistance and high-impact strength.

“

3D printing has emerged as the ultimate tool for local manufacturing, reducing the production chain to the bare minimum. With COVID-19 emergency, this technology provides the opportunity to efficiently produce affordable tools, which are now essential to help save lives. This is indisputably the most important challenge we have faced as designers and makers, but also the best use of design intuition and technology.

Nagami Team

”

Please contact Nagami’s press office, mint LIST (Maria Azzurra Rossi, Giulia Milza)

Nagami Team:

Manuel Jiménez García, Miguel Angel Jiménez García, Ignacio Viguera Ochoa, Alejandro Nieto Jiménez, Luis de la Parra García, Patricia San Segundo Galán, India Carazo, Anna Szonyi

Project Collaborators and sponsors

3D printing support: CV19_Fab_Ávila

Technology support: ABB

Rubber Bands sponsor: Mercería Padilla, Mercería Mordissko, Mercería Ysali, Comunidad china abulense

Transparency Film sponsor: Tecnipapel, Imagen, Librería letras, Librería Atenea, App Las Damas, Hiper Office, Politécnica de Ávila, BricoCentro

Printing Material sponsor: Politécnica de Ávila, Jose Luis Jiménez

Plastic Filament: Sicnova

Packaging: Blueboxes Smart Wash, Esembal

Tool support: Mecanizados Jimar, Mecanizados Castilla